Semester Results

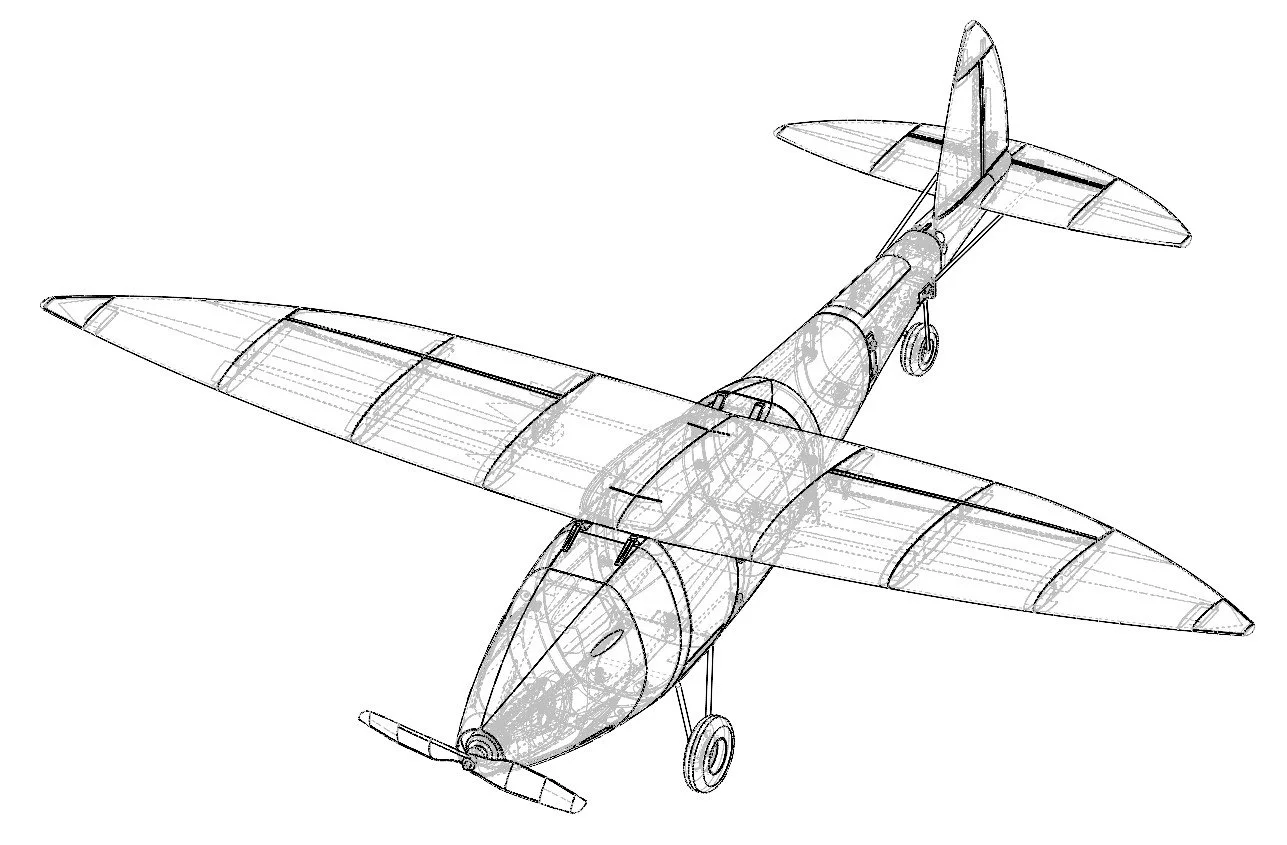

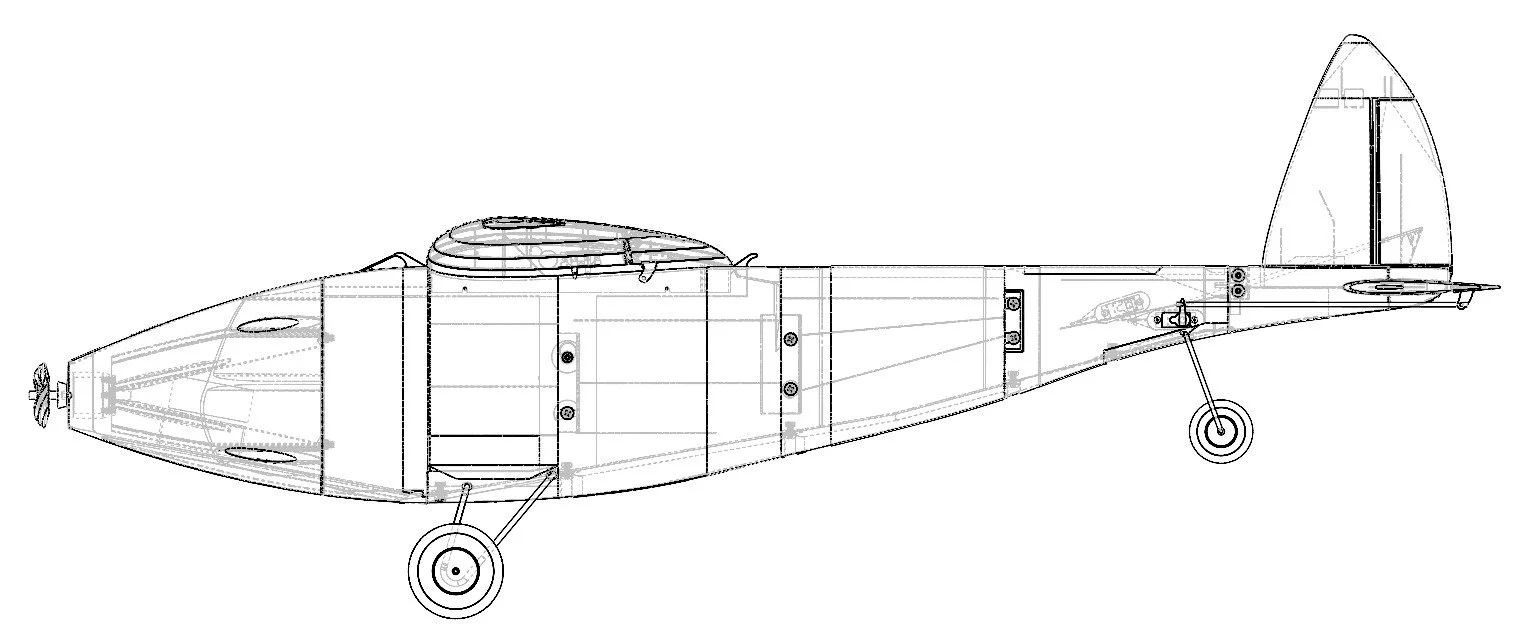

The design of the airplane after iteration.

The large wing span combined with the large vertical tail helped ensure stability of the aircraft.

Large flaperons became the basis for wing control, while relatively massive tail controls were included.

This was our ultimate Manufactured Design

Out on the test field on a day of good weather, we sent the aircraft up. Despite a slight crosswind on take off, it managed to get off the ground, climb, and stay steady in the air.

Landing was questionable, due to difficulties of flying an RC plane, however our pilot managed to get it down in one piece.

With the airplane coming down, we all excitedly gathered around at the landing sight. While the runway was missed, the plane held up wonderfully.

After so many hundreds of hours of work, this aircraft had succeeded in its mission, with flight time and performance to spare. Truly and incredible moment seeing it land.

Final Presentation

With the plane having flown, we prepared our presentation of the long term design of the aircraft. While not covering every intricate detail of the design, the overall though process and selection is shown.

After 45 minutes, guests of the presentation were welcomed to ask questions. Though some of them made us think, the presentation as a whole was satisfactory to us and to the guests who so graciously listened to our most challenging semester's story.

Alternative Design Considerations

The semester was not a simple one. Designing, building, and flying a fully functional aircraft of any size is no small feat. And sometimes concepts of multiple types are tried.

In this concept, an aircraft was created from completely 3D printed parts - the wings, tail, and fuselage were all PLA plastics. The wing-spar was the only body component that wasn't made from PLA, choosing a thin aluminum bar for its rigidity.

The CAD for this concept was rather intensive, taking myself nearly 100 hours to produce. Along the way, I figured out a lot regarding rapid prototyping, the quirks of SOLIDWORKS surfaces, and how quickly one part can interfere with another. While the results weren't great, this CAD I am nonetheless proud of.

Results:

The aircraft would ultimately not make it off the runway. Due to the culmination of landing gear strafing, crosswinds at takeoff, and issues with the mass of the 3D prints, it never saw its madden flight before time ran out.

Reflections

Without a doubt, this semester was the hardest I had by that point. After spending nearly 150 hours in CAD, another 150 hours manufacturing, and some 100 hours in lecture, researching, and communicating with my team, I had developed a lot. I accomplish my personal goals of designing a 3D printable aircraft from SOLIDWORK's surfaces toolset, built 4 fully assembled airplanes, engaged with a wide group of people in my department, and furthered my skills in manufacturing of different types.

So in all, it was a good experience. I further developed my ability to do carbon fiber layups, made 3D parts of rather high complexity (developing a much more efficient design pipeline to do so), grew in my interpersonal skills, wrote more pages of documentation than ever before, and researched such a great deal about aircraft design I never knew existed prior. While it was a long process with quite literal blood, sweat, and tears put into it, the project was able to get off the ground in the most satisfying moment in my engineering path to date.